Small businesses often dream about taking production into their own hands. It’s a great way to show that you’re being more self-sufficient as a company and it enables you to take control of the production process. This is extremely important for things such as establishing sustainable manufacturing processes and also controlling the quality of your products down to the raw materials you use. With so much control comes far more possibilities, and it’s a respectable goal to aim for as a startup.

Unfortunately, setting up your own manufacturing processes can be prohibitively expensive. There’s a massive investment involved and you typically don’t want to be wasting your time and money on something like this when there are cheaper options available for small companies. Outsourcing production is far cheaper and it’s usually good enough for most small businesses. But if you’re itching to get started with our own production and believe that it’s the most effective way for your business to grow, then here are a couple of considerations to keep in mind first.

Is your product really in demand?

First, decide if the product you’ve made is really in such high demand that you can actually profit from setting up your own production process. If you’ve built a product that will sell then it’ll be clear because you’ll always be sold out and your current outsourced production facility won’t be able to keep up. If you believe that this is the case for your product, then you may want to consider starting up a small production line of your own.

With that said, you don’t really need to rent out an entire warehouse or factory of your own. In many cases, you can work with existing manufacturing facilities that can change their machines to fit your needs. Think of it more as renting a facility instead of building your own.

Have you experienced issues with your current manufacturer?

If your current manufacturing partner has caused many issues in the past then it’s a good idea to either consider switching or taking it into your own hands. The big issue with working with another manufacturer is that you can’t fine-tune everything and you typically can’t go into the factory to examine the workmanship. As a result, it can lead to some manufacturing defects, it can lead to quality control issues, and it might cause customers to lose faith in your company if they’re being shipped directly from the factory to buyers.

If you’re facing issues with your current manufacturer then you’ll want to consider swapping or taking things into your own hands. Having more control over your production process means you won’t be able to shift the blame onto your partners. Instead, you’ll take the blame if there are issues, but this responsibility can actually make your business more trustworthy and reliable in the eyes of consumers.

Do you have local specialists that could assist with your production process?

It’s possible to set up a rather small production process if you don’t need a lot of expensive and heavy machinery. People usually think that production facilities require massive warehouses and conveyor belts like a film, but the reality is that a production process could just mean a few prosumer tools inside of a garage.

However, regardless of what the production process involves, you’ll want to ensure that you’re working with local specialists that can make it happen. Companies like GFF Power can address power delivery concerns which can be a problem if you’re using high-power machinery. Similarly, you may need to work with a company that can help you custom-design tools, workbenches and other things that you might need to start your own production processes.

Are you willing to invest in a production facility and have future plans for it?

If you’re going to scale up your operations then you’ll eventually be looking at investing in a production facility. However, this can still be really expensive even for a growing business and it’s a massive investment of time and effort as well. However, with the right partners and specialists on your team, you can make it happen.

You’ll also want to think about your future plans for the production facility. Are you able to diversify your production lines in the future? Will you have enough staff to work there? Will you eventually move your current production lines to a larger location? There are lots of different things to consider and it’s not something you can just rush into.

Want to learn more?

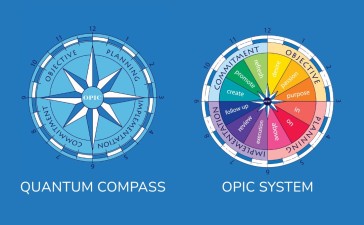

- Just starting out? CLICK HERE

- Been working in your business for two years or more? CLICK HERE

We’re here to help you to take action just like we’ve helped thousands of other entrepreneurs, business owners and creative professionals all around the globe.

Now is the time to let your passion SHINE.

Now is the time to Make Tomorrow Today!

To your success,

Vinh Van Lam & Stuart Horrex

Your Coaches ArtSHINE industries